Li Jun: Bringing Chinese caviar to dinner tables worldwide

文:《一带一路报道》全媒体记者 贾琪

“可能很多人都还不知道,全球12%的鱼子酱产自四川。雅安市天全县利用纯净高山冰雪融水养殖鲟鱼,去年生产了50吨鱼子酱,远销俄罗斯等欧美国家。”在今年4月播出的央视节目中,四川省政府官员推介了四川润兆渔业有限公司(以下简称“润兆渔业”)的鱼子酱。

众所周知,鱼子酱原产欧洲,与松露、鹅肝齐名,作为世界三大顶级奢侈美食之一,被誉为“黑色软黄金”,向来是美食家们的“座上宾”。

什么样的鱼子酱能够畅销海外,改写世界鱼子酱产业格局?其背后的关键人物润兆渔业创始人李军经历了怎样的波折?又有何制胜法宝?

用鱼子酱烹饪美食

孤注一掷养鲟鱼

采访约在8月25日早上。记者走进位于成都的润兆渔业本部,眼前的李军身着黑色T恤,戴着一副框架眼镜,面带微笑,言谈中尽显平和、亲切。

万事开头难,当初如何想到要养殖鲟鱼?伴着提问,李军的思绪回到了2002年。

那年春节前夕,李军在朋友组织的饭局上第一次吃到鱼子酱。“当时就觉得挺新奇的,没想到鲟鱼卵还能做出这么好吃的东西来。”大连水产学院毕业(现名大连海洋大学)的李军嗅到了其中的商机。

彼时,《濒危野生动植物种国际贸易公约》对捕杀野生鲟鱼进行严格限制,国际鱼子酱产业逐渐呈现出散点、家庭作坊式分布,未形成产业集群。

尽管没有养殖经验,再加之鲟鱼生长周期长、投入成本大,李军却判定养殖鲟鱼是一片蓝海市场。因此,他力排众议,押上之前养殖鲇鱼积攒的百万身家,决定“赌上一把”。

为最大限度降低风险,李军采取“短线养长线”方案,即一边养殖短期内可供出售的商品鲟鱼,一边用赚到的钱养殖需要七八年才能产卵的鲟鱼苗。

说干就干!他将宏图分为两部分同步进行:一是从国外采购鲟鱼苗,在国内考察选址、建设养殖基地,多方学习攻克养殖技术关。二是为稳定商品鲟鱼销售渠道,锁定当时成都青石桥水产市场最大经销商——杨成毅。

然而,与杨成毅多次见面,多次被拒。

继续磕,死缠烂打肯定不行,深思熟虑之后,李军两招智取。

第一招,不提合作,请求租用杨成毅一个鱼缸,方便周边客户取货。

一个多月里,到店拿鱼的客人很多,销量远高于杨成毅自己养的商品鲟鱼。杨成毅一眼识破,这不过是李军的商业手段而已,自是不为所动。

李军也料到了杨成毅的反应。第二招,继续送鱼,鱼儿三天无人问津。

这一次,换杨成毅开始着急,他坐不住了,怕鱼死在自己手上,便主动打电话给李军:“这个鱼不能放太久,要翻肚,你赶紧来取回去。”

接到电话的李军只道:“没关系,死了算我的。”口头上答应,但就是找各种理由不去取鱼。

结果,鲟鱼在缸里一放就是十多天,却安然无恙。杨成毅最终被李军商品鲟鱼的品质折服,同意签订合同。

当年,杨成毅为李军销售商品鲟鱼50多万斤。并且,双方约定,要稳定成都商品鲟鱼市场,不随大行情波动而改变鲟鱼价格,按计划数量进行销售。

2002—2012年,商品鲟鱼的价格一路回升,靠着稳定的销售渠道,李军的商品鲟鱼及鲟鱼苗每年销售额超3000万元,成了四川名副其实的“鲟鱼大亨”。

高薪聘请伊朗大师

十年磨砺宝剑成。在经历了按比例换水、定量投喂、流水养殖等一系列波折和地震、山洪等自然灾害后,李军决定“把鸡蛋放在不同篮子里”,在四川、甘肃、重庆等地建立起十余处养殖基地,待产卵的鲟鱼上万条。

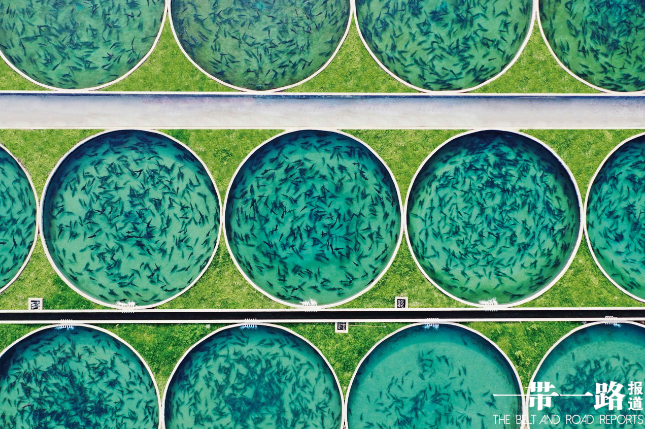

阳光下,一座座圆形养殖池如一颗颗绿宝石逐一排开,各类品种的鲟鱼在欢快游动,不时溅起阵阵水花。

畅聊中,李军提及养殖鲟鱼的水质至关重要,“天全县河流众多,水质常年稳居全国前列、全省第一,水温常年保持在23℃以下,非常适合冷水鱼养殖。”2012年,润兆渔业扩大产值,将新基地落户雅安市天全县。

一切都在向着好的方向发展。同年年底,公司收到了第一笔鱼子酱订单。

然而,就在发货前夕,李军感到隐隐不安。他来到库房,打开鱼子酱罐口,赫然发现罐内四周长满了白毛。

原来,法国客户在飞赴中国考察了润兆渔业鲟鱼养殖环境后非常满意,但出于时间紧迫,没有考察生产车间,直接预定了产品。而当时,润兆渔业并没有成熟的鱼子酱加工经验,采取的是中国传统方式做酱,导致鱼子酱被细菌污染,产生霉变。就这样,这笔来之不易的订单化为乌有,赔偿违约金数十万元。

“一开始的想法很简单,认为只要有好鱼,就会有好的鱼子酱。”忆及往事,李军感慨道,“大多数环节都是从零起步,我们每一步都踩过坑,所有的成功都是在不断试错中摸索出来的。”

经一事,长一智。为学习专业的鱼子酱加工经验,2013年,李军高薪从鱼子酱传统生产大国伊朗请来鱼子酱大师突凡尼传授手艺。

操作台前,大家看得目瞪口呆。原来,鱼子酱要在无菌环境下制作,为保证其味道鲜美,17道工序掐秒衔接,需在15分钟内一气呵成:杀鱼、剖腹、取卵、清洗、拌盐……盐分浓度、搅拌力度和时间长短都极为讲究,一丝一毫的差异,都会影响鱼卵的口感和味道。

此外,李军还斥资百万元从国外购回最先进的鱼子酱生产线,攻克产品质量关。

2013年9月,习近平主席首提“一带一路”倡议。乘着“引进来”与“走出去”的时代东风,跟众多川企一样,润兆渔业踊跃“出海”,竞逐国际舞台。

鲟鱼养殖

三顾茅庐叩开国际市场大门

不知不觉,时间已到中午,访谈移至餐厅。在李军的细心指导下,记者品尝了润兆渔业核心产品“芙思塔”俄罗斯鲟鱼子酱,立时被这美味佳肴“种草”!

轻轻揭开红色盖帽,用贝壳小勺舀一勺圆润饱满、色泽乌亮的鱼子酱于虎口处,再放进口中用舌尖和上颚碾碎,口中顿觉咸香四溢。

李军坦言,想要进入欧美主流消费市场非常不易,尽管产品已通过国内外各项许可和认证,完全符合国际标准,但前期却面临一个重要课题:如何消除国际市场的“傲慢与偏见”,让其接受来自中国的食材。

拜访客户、参加展会、寄送样品……李军带领销售团队奔波于欧洲各地,“最夸张的时候,10天时间我们开车上万公里,见了20多位客户,但只能讨回一点零星的订单。”

见“广撒鱼,多捞网”的方式收效甚微,李军又改变策略,将目光瞄准世界鱼子酱顶级品牌:法国裴卓仙(Petrossian)。只要打通这家鱼子酱产业头部商家销售渠道,就不愁拿不到欧美市场的入场券。

然而,打电话,无人接听;发邮件,石沉大海;登门拜访,苦等3小时,进去不到5分钟就被送客……李军记得,那是2013年的冬天,巴黎的气温很低,天空下着瓢泼大雨,销售团队冻得面色发青、嘴唇发紫。

“欧洲人做生意很谨慎,一般要观察3到5年才愿意合作。这时候,拼的就是三顾茅庐的诚意和毅力。”李军道,通过一而再、再而三的努力,裴卓仙终于被打动,两次派人飞往四川对润兆渔业进行全方位考察,并提出几十项改进要求。2016年,润兆渔业正式成为该品牌供应商。

紧接着,润兆渔业生产的鱼子酱被摆进老佛爷百货食品专柜、迪拜帆船酒店,国际订单如雪片般纷至沓来,畅销法国、卢森堡、美国、加拿大等近30个国家,纵使疫情期间,销售不降反增。

如今,随着消费升级和生活方式的变化,国内越来越多的人群接受了鱼子酱消费文化。李军便将目光从国外拉回国内,开启国际、国内“两条腿走路”模式,与高端星级酒店、电商平台合作,使鱼子酱在国内开花结果。

目前,润兆渔业已经建成从养殖端的苗种繁育、商品鱼养殖、种鱼养殖,到加工端的鱼子酱及鱼肉,再到销售环节的鲟鱼鲜活产品、鱼子酱、鱼肉产品,涵盖国内销售和国际贸易的完善产业链。

“下一步,我们将在美容美妆市场做深度开发和合作,推出基于鲟鱼子酱的美容美妆产品,激活中国巨大的消费市场。”谈及未来规划,李军并不着急公司上市,他更想稳扎稳打,以质说话。

渔业基地

“You may be surprised to know that 12% of the world’s caviar comes from Sichuan Province. Tianquan County in Ya’an City leverages the pure, high-mountain ice and snow meltwater to cultivate sturgeon. Last year, a total of 50 tons of caviar was produced. They were exported to countries in Europe and America, including Russia.” During a CCTV program broadcast in April this year, officials from the Sichuan provincial government highlighted the caviar produced by Sichuan Runzhao Fisheries Co., Ltd. (hereinafter referred to as “Runzhao Fisheries”).

As is well known, caviar originated in Europe and, along with truffles and foie gras, it is one of the world’s three major luxury foods and is hailed as the “black gold”, always being the guest of honor among gourmets.

What kind of caviar can become a global bestseller and reshape the world's caviar industry? What kind of twists and turns has Li Jun, the key figure and founder of Runzhao Fisheries, gone through? And what is his winning trick?

The great gamble on sturgeon

The interview was scheduled for the morning of August 25. As the journalist walked into the headquarters of Runzhao Fisheries in Chengdu, Li Jun, dressed in a black T-shirt and wearing a pair of glasses, greeted the reporter with a smile, displaying a calm, friendly demeanor in his conversation.

Nothing is ever easy at the beginning. How did you come up with the idea of farming sturgeon? This question brought Li Jun’s thoughts back to 2002.

On the eve of the Spring Festival that year, Li Jun tasted caviar for the first time at a dinner party with his friends. “It was quite a novel experience at that time. I didn’t know that sturgeon eggs could turn into such delicious food.” Li Jun, then a graduate of Dalian Fisheries University (now Dalian Ocean University), sensed a business opportunity.

At that time, the Convention on International Trade in Endangered Species of Wild Fauna and Flora imposed strict restrictions on hunting wild sturgeons. The international caviar industry gradually showed a scattered and family-style distribution without forming industrial clusters.

Despite his lack of farming experience and sturgeon’s long growth cycle and high investment cost, Li Jun determined that sturgeon farming would have a promising market. Regardless of disagreeing voices, he firmly decided to invest his earlier earnings from catfish farming into this great gamble.

To minimize risks, Li Jun adopted a “dual-track” approach. While farming sturgeon that could be sold in the short term, he used the money earned to nurture sturgeon fry, which would only start laying eggs after seven to eight years.

He took swift action! The grand plan was divided into two simultaneous parts: One was to purchase sturgeon fry from abroad, inspect sites domestically, build farming bases, and learn to overcome breeding technology barriers. The second part was to secure a stable sales channel for commercial sturgeon. He sought cooperation with Yang Chengyi, the largest distributor in Chengd’s Qingshiqiao aquatic market at that time.

However, he was turned down several times by Yang Chengyi.

Seeing that this didn’t work, Li Jun came up with two smart moves after contemplation.

First, he didn’t ask for a partnership but requested to rent a fish tank from Yang Chengyi to facilitate nearby customers in picking up orders.

In just over a month, many customers came to the shop to pick up fish, and the sales volume far exceeded that of the commercial sturgeons raised by Yang Chengyi himself. Yang saw this as Li Jun’s business tactic but did not take any action.

And all of these were merely part of Li Jun’s plan. Li Jun’s second move was to keep supplying. This time, no sturgeon was sold for three consecutive days.

This made Yang Chengyi very anxious. Fearing the fish would perish in his hands, he called Li Jun, “This fish can’t stay for long. They will soon die if you don’t come take them back. Hurry!”

When Li Jun received the call, he calmly replied, “They’ll be fine. Don’t worry, if they die, it’s on me.” He verbally agreed but kept finding excuses not to take back the fish.

As a result, the sturgeons were left in the tank for more than ten days and yet remained lively. Yang Chengyi was finally swayed by the quality of Li Jun’s commercial sturgeon and agreed to sign a contract.

That year, Yang Chengyi sold more than 500,000 jin (250,000 kg) of Li Jun’s commercial sturgeon. In addition, they agreed to stabilize the market price of commercial sturgeon regardless of market fluctuations and carry out sales according to a planned quantity.

From 2002 to 2012, the price of commercial sturgeon kept rising. With a stable sales channel, Li Jun’s annual sales volume of commercial sturgeon and sturgeon fry exceeded 30 million yuan, making him a veritable “Sturgeon Tycoon” in Sichuan.

鱼子酱加工厂

Learn from an Iranian master

After ten years of relentless effort and perseverance, Li Jun finally achieved a significant milestone in his business. After experiencing a series of twists and turns, including proportional water change, quantitative feeding, flowing water cultivation, and natural disasters such as earthquakes and floods, Li Jun decided to “put the eggs in different baskets”, establishing more than ten farming bases in Sichuan, Gansu and Chongqing. These bases are home to tens of thousands of sturgeons waiting to spawn.

Bathing in sunlight, a tapestry of round farm ponds glitter like emeralds, home to an array of sturgeon that swim cheerfully, now and then sending up a splash.

During the chat, Li Jun brought up the importance of water quality in sturgeon farming. “Tianquan County has a large number of rivers, and its water quality ranks at the top nationwide and first in the province, and the water temperature remains below 23℃ all year round, which is very suitable for the cultivation of cold-water fish.” In 2012, Runzhao Fisheries expanded its output value and established a new base in Tianquan County, Ya’an City.

Everything was moving in a positive direction. At the end of the same year, the company received its first caviar order.

However, on the eve of delivery, Li Jun felt an uneasy premonition. He went into the storage room, opened a caviar jar, and to his shock, it was filled with white mold.

A while ago, a French client, satisfied after inspecting the farming environment of Runzhao Fisheries, placed an order without checking the production workshop due to time constraints. Unfortunately, at that time, Runzhao Fisheries did not have mature caviar processing experience and used a traditional method to make the caviar, causing it to become contaminated with bacteria and mold. Thus, the hard-won order was lost, resulting in a breach of contract penalty of hundreds of thousands of yuan.

“My initial idea was simple. I thought that good fish would naturally lead to good caviar.” Reflecting on the past, Li Jun sighed and said: “We started from scratch, and we’ve stumbled over every step. All our success came from constant trial and error.”

Experience is the best teacher. To learn professional caviar processing techniques, in 2013, Li Jun paid a high salary to bring a master caviar processor named Toufanian from Iran, a traditional major producer of caviar, to teach them the craft.

Watching the master at processing table, everyone was stunned. It turned out that caviar must be made in a sterile environment. To ensure its delicious taste, 17 steps should be completed within 15 minutes: killing the fish, opening its belly, extracting eggs, washing, salting, and so on. The concentration of salt, the intensity of stirring, and the duration were all critical factors, where the slightest variation could affect the texture and taste of the caviar.

In addition, Li Jun also spent millions of yuan to purchase the most advanced caviar production line from abroad to overcome the product quality barrier.

In September 2013, General Secretary Xi Jinping first put forward the Belt and Road Initiative. Riding the tailwind of “bringing in” and “going global”, Runzhao Fisheries, like many Sichuan enterprises, eagerly ventured abroad to compete on the international stage.

鱼子酱加工车间

Knocking on the door of the international market through persistent efforts

Time flew and it was noon before anyone realized. The interview moved to the restaurant. Under the meticulous guidance of Li Jun, the journalist tasted Runzhao Fisheries’s core product, “Frosista” Russian sturgeon caviar, and instantly fell in love with this delicacy!

The journalist gently lifted the red cap, took a full and lustrous scoop of caviar to the back of the hand, and then placed it into the mouth, rolling and crumbling it between the tongue and the upper palate, immediately savoring a luscious salty flavor.

Li Jun admitted that entering the mainstream consumer market in Europe and America was not easy. Even though their products had obtained all domestic and foreign permissions and certifications and fully complied with international standards, there was still a crucial issue in the initial stages: how to eliminate the prejudice of the international market and make people accept ingredients from China.

Visiting customers, attending exhibitions, sending samples... Li Jun led the sales team on their trips across Europe. “During the most difficult times, we drove tens of thousands of kilometers in 10 days, met with more than 20 customers, but only ended up with a meager handful of orders.”

With little success in extensive seeking, Li Jun changed his strategy and targeted the French company Petrossian, one of the top brands in the global caviar industry. As long as he could break into this industry-leading sales channel, he wouldn’t worry about gaining admission to the European and American markets.

However, his calls went unanswered, emails were ignored, and visits were short-lived despite long waits…Li Jun remembered that it was the winter of 2013. The temperature in Paris was very low, and heavy rain poured. The sales team was chilled to the bone, their faces a ghastly shade of blue and their lips tinged with purple from the biting cold.

“The Europeans are very cautious in doing business, and it takes three to five years of observation before they become willing to cooperate. At this point, it’s about persistence and sincerity.” Li Jun said, through repeated efforts, Petrossian was finally moved. The French company sent people to Sichuan twice for comprehensive investigations of Runzhao Fisheries and proposed dozens of improvement requirements. In 2016, Runzhao Fisheries officially became a supplier to this brand.

Following that, caviar produced by Runzhao Fisheries was placed in Galeries Lafayette's food counter and the Burj Al Arab hotel. International orders poured in like a flurry of snowflakes, and Runzhao Fisheries’ products were sold in nearly 30 countries, including France, Luxembourg, the United States and Canada. Even during the Covid-19 pandemic, the sales continued to rise.

鱼子酱产品图

Nowadays, with the upgrading of domestic consumption and changes in lifestyles, more and more people in China have accepted the culture of caviar consumption. Li Jun shifted his focus back from foreign to domestic markets, initiating a dual strategy of domestic and international sales. He collaborated with high-end star-rated hotels and e-commerce platforms, enabling caviar to flourish in China.

Currently, Runzhao Fisheries has established a complete industrial chain, from breeding fry, commercial fish farming, and broodstock farming at the cultivation end, to caviar and fish processing at the manufacturing end, and then to selling various fresh sturgeon products, caviar, and fish products at the sales end. This chain encompasses both domestic sales and international trade.

“Moving forward, we plan to carry out in-depth development and cooperation in the beauty and cosmetics market, launching beauty and makeup products based on caviar. This will activate China’s tremendous consumer market.” Speaking of future plans, Li Jun wasn't in a hurry for the company to go public. He preferred to play steadily and speak with quality.

来源:《一带一路报道(中英文)》2023年10月特刊

【未经授权,严禁转载!联系电话028-86968276】