文/王琪琪

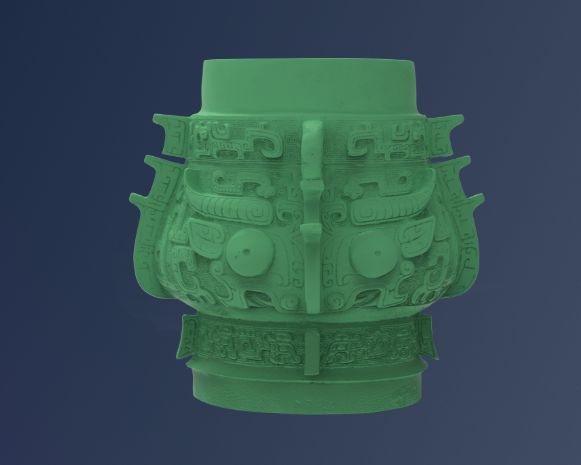

3D打印的三星堆主题潮玩手办、比普通鞋轻60%的机甲风运动鞋、为膝关节患者量身定制的“假骨头”……这些看似不相干的产品,其实背后都源自一项技术——增材制造。不同于传统“减材制造”的削切打磨(如木雕、萝卜雕花),它像搭积木般堆积材料,“打印”出立体物件。

在四川泸州,泸州航空发展投资集团有限公司(以下简称“泸州航发”)仅用3年时间,就凭借这项技术实现创新突破——为患者定制医疗植入体,打印火箭零件、卫星组件等精密部件。从文化传承到医疗健康,从日常生活到尖端制造,泸州航发利用增材制造技术进行的创新实践,正汇聚成国家培育新质生产力的重要力量。

泸州航发集团园区航拍图

破局:从0到1

2017年,在国家推进国有企业的战略性重组和专业化整合背景下,承担着发展航空航天产业使命的泸州航发成立了。成立之初,肩负重要使命的企业却陷入踌躇:盘活国有资产的具体抓手是什么?现金流与营收从何处突破?怎样创新技术?市场又在哪里?诸多问题让企业一时徘徊无解。

迷茫之际,泸州航发找到泸州籍中国工程院院士王华明。多年前,王院士就提出:“增材制造是航空发动机等高端装备制造的核心技术,也是实现精密成型的关键路径,未来将广泛应用于千家万户。”这一判断精准切中了泸州航发突破发展瓶颈的需求。于是,企业果断聚焦增材制造赛道,开启从技术攻坚到产业生态成型“从0到1”的破局之路。

找到突破点后并非一路坦途,质疑声接踵而至:“作为三、四线城市,如何与一线城市竞争?”“重资产研发投入何时才能见效?”……泸州航发党委委员、副总经理罗艳的回答是:“我们没有扎堆传统产业,而是以产业投资公司的定位重构发展思路,果断砍掉非核心项目,把资源集中投向增材制造这个‘火种’。”

技术攻关初期,设备调试屡遭瓶颈、产品良率长期低位,企业面临严峻考验。“泸州市委、市政府以战略眼光包容创新的风险,为培育新质生产力提供大力支持。”罗艳回忆,“近3年高投入低产出的日子并不好过,但技术突破必然伴随阵痛。认准方向就要保持战略定力。”2025年,由泸州航发、知来投资等资本总投资5亿元的博理超高速3D打印智能云工厂项目,签约落户泸州市龙马潭区。该项目从签约到一期投产仅用数月,实现了从“签约”到“量产”的快速跨越,全面投产后预计年产值可达3亿元。泸州航发还加速布局航天、消费、医疗三大赛道,进一步强化行业引领地位。

泸州航发集团副总经理 罗艳

发展:走进“千家万户”

持续的发展验证了王院士的判断——“增材制造迟早会成为千家万户的产业。”泸州航发以增材制造为核心,向上游筑牢了“材料根基”:不仅研发出能造精密零件的钛合金、高温合金粉末(纯度达国际级),更将成渝地区双城经济圈的战略优势转化为产业动能,探索出“成渝研发、泸州转化”的联动路径。

成渝高校密集、科研资源丰富,泸州航发瞄准这一优势,与高校及科研院所合作攻坚金属粉末关键技术(从熔炼工艺到粉末纯度控制),把“从0到1”的创新留在成渝;泸州则凭借本地化工配套完善、政策支持给力、生产空间充足的条件,快速承接这些成果,建起年产能超2000吨、西南最大金属粉末基地,不仅满足本地需求,更辐射西南、华东企业——这一产能规模在全国同类金属粉末生产基地中位居前列,相当于可满足近千家中小型增材制造企业的年均用粉需求,为产业链“有米下锅”提供了硬核支撑。

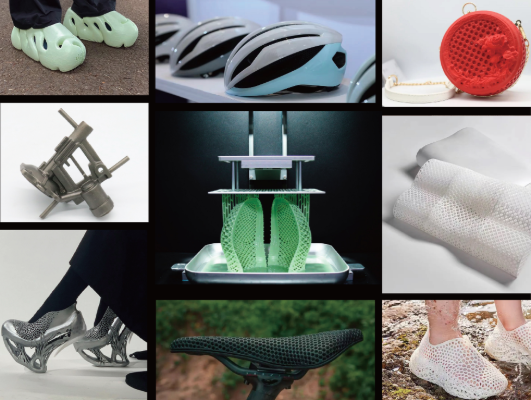

“研发在成渝、制造在泸州”的模式,既破解了材料“做不出、做不好”的难题,更通过优势互补,让两地的创新链与产业链紧密咬合,为增材制造走向“千家万户”备足了“好米”。在产业链中游,泸州航发给生产装上“硬核引擎”——打印大尺寸金属件的精密装备,操作简化如“傻瓜相机”,效率翻倍,更填补国产高端设备空白,让精密制造不再受制于人。下游,技术扎进生活“开花结果”:在航空航天领域,建3万平方米“超级工厂”,服务60余家客户,项目成国家级示范;在医疗健康领域,依托泸州三甲医院资源,研发贴合人体曲面的精准医疗器械,帮助医生更精准治疗,惠及更多患者;在大众消费领域,2小时就能“打印”出一双符合国际一线奢侈品严苛标准的运动鞋——相当于传统手工制鞋10倍的效率、普通产线3倍的产能。日产四五千双的“泸州造”潮鞋,正从实验室的黑科技走向全球消费者的脚尖。这不仅是制鞋业的效率革命,更是泸州航发以增材制造为突破口,推动产业链从“卡脖子”到“闯天下”的生动缩影。

3D打印文创

突破:构建企业护城河

从潮玩到航天精密件,从定制医疗植入体到2小时“打印”的运动鞋,泸州航发用3年将增材制造锻造成“产业密钥”。比技术更值得关注的是,这家地方国企如何激活新质生产力深层动能?

当增材制造还被视为“小众技术”时,泸州航发以“产业探路者”姿态切入,面对“三、四线城市的国企能否搞高端制造”的质疑,以“外科手术式”精准决策砍掉非核心业务,聚焦技术攻坚与生态培育。这种“战略瘦身”是为创新开路,让企业在航空航天等高附加值领域站稳脚跟,攒下“第一桶金”,并用系统思维编织产业上下游网络。

突破与创新的故事,并非单靠某一方的力量书写,而是“科学家+企业家+政府”三方拧成一股绳的结果。在产业网络的搭建中,科研力量像深埋地下的“根系”——泸州航发联合华中科技大学、西北工业大学等高校共建国家级创新中心,把增材制造的核心技术牢牢攥在手中,构建企业护城河。

从日常生活到尖端制造,增材制造走进“千家万户”

政府的角色,既是包容创新的“守护者”——以“试错容错”机制为创新兜底,将短期试错成本转化为长期经验资产,更是本地资源的“赋能者”——依托泸州医疗、装备制造等特色产业基础,发挥国有平台公司资源整合优势,将资本、技术、市场资源串联成网,为新兴产业链的延链、补链、强链提供精准支撑。仅在资金层面就有数据显示,“十四五”以来,泸州市助力企业获得信用贷款达144.12亿元,其中制造业、科技型企业受益显著。这形成了“产业壮大—信用积累—金融支持—再发展”的良性循环,强化了产业集群的韧性与活力。

企业家的市场嗅觉与资源整合能力,则像托举根系的“土壤”——依托国有资本的资源优势,引入社会资本共建基金,推动技术研发与市场应用正向循环,把实验室“样品”变成能大规模交付的“商品”。年轻化管理团队展现出敏锐的战略眼光:他们主动赴长三角、粤港澳大湾区调研学习,将前沿经验与本地优势结合,以前瞻性思维布局全球——一边“引进来”全球创新资源突破发展瓶颈;一边“走出去”扎根海南、新疆等战略节点,在自贸港连接东南亚及RCEP市场,在中亚口岸辐射俄能源带,以差异化口岸打通“陆海双循环”。

如今,泸州航发通过海南基地服务东南亚,经新疆口岸辐射中亚,以高性价比与定制化方案激活沿线制造业升级。这不仅为共建“一带一路”提供了可复制的产业协作样本,更让中国高端制造在国际舞台上拥有了更强的话语权。

3D-printed Sanxingdui-themed designer figurines, mecha-inspired sneakers that are 60% lighter than conventional shoes, and custom-made “artificial bones” for knee patients… Although these products may seem unrelated, they all originate from the same technology—additive manufacturing. Unlike traditional “subtractive manufacturing” methods such as cutting and polishing (for example, in woodcarving or radish carving), additive manufacturing stacks materials like building blocks to “print” three-dimensional objects.

In Luzhou, Sichuan, Luzhou Aviation Development Investment Group Co., Ltd. (referred to as “LADIC”) utilized this technology to achieve innovative breakthroughs in just three years—customizing medical implants for patients and 3D printing precision parts such as rocket and satellite components. From cultural heritage to healthcare, and from daily life to advanced manufacturing, LADIC’s innovative applications of additive manufacturing technology are becoming a key driver in cultivating new quality productive forces nationwide.

Start: From 0 to 1

In 2017, against the backdrop of the national push for strategic restructuring and specialized integration of state-owned enterprises, LADIC was established to fulfill the mission of advancing the aerospace industry. At its inception, the company, burdened with a vital mission, wavered: What concrete measures could be taken to revitalize state-owned assets? How could cash flow and revenue be improved? How should technology be innovated? Where is the market opportunity? A series of challenges left the company temporarily at an impasse.

During this period of uncertainty, LADIC sought guidance from Wang Huaming, an academician of the Chinese Academy of Engineering and a native of Luzhou. Years ago, Academician Wang asserted, “Additive manufacturing is the core technology for producing high-end equipment such as aircraft engines, and it is the key pathway for achieving precision forming. In the future, it will see widespread application in thousands of households.” This insight precisely addressed LADIC’s need to overcome development bottlenecks. As a result, the company decisively shifted its focus to additive manufacturing, embarking on a breakthrough journey from tackling technological challenges to shaping an industrial ecosystem—a “zero to one” transformation.

After identifying the breakthrough point, the path forward was far from smooth. Doubts arose one after another: “How can Luzhou, a third- or even fourth-tier city, compete with first-tier cities?” “When will the returns from heavy investment in R&D materialize?”… Luo Yan, member of the CPC Committee and Deputy General Manager of LADIC, revealed in an interview: “We did not cluster around traditional industries. Instead, we restructured our development strategy based on the positioning of an industrial investment company, decisively eliminating non-core projects and concentrating resources on additive manufacturing as our ‘spark.’”

During the initial stage of tackling technological challenges, equipment debugging repeatedly encountered bottlenecks, and product yield rates remained consistently low, putting the enterprise under severe strain. “The CPC Luzhou Municipal Committee and the People’s Government of Luzhou Municipality took a strategic perspective in embracing the risks of innovation, providing strong support for cultivating new quality productive forces,” Luo Yan recalled. “The first three years of high investment and low output were not easy, but any technological breakthrough inevitably comes with growing pains. Once the direction is clear, we must maintain strategic focus.” In 2025, the PollyPolymer Ultra-High-Speed 3D Printing Intelligent Cloud Factory Project, jointly funded by LADIC and Zhilai Investment with a total investment of 500 million yuan, was signed and settled in Longmatan District, Luzhou. The project took only a few months to move from signing to launching its first phase of production, achieving a rapid leap from “contract signing” to “mass production.” After reaching full operational capacity, the expected annual output value is 300 million yuan. LADIC is also accelerating its deployment in the three key sectors of aerospace, consumer products, and healthcare, further solidifying its industry leadership.

Development: Reaching thousands of households

Its ongoing development has validated Academician Wang’s judgment that “additive manufacturing will eventually become an industry present in thousands of households.” Centered on additive manufacturing, LADIC has built a solid “material foundation” upstream: it has not only developed titanium alloy and high-temperature alloy powders for precision parts—reaching international purity standards—but has also transformed the strategic advantages of the Chengdu-Chongqing economic circle into industrial momentum, exploring a linkage pathway of “R&D in Chengdu and Chongqing, transformation in Luzhou.”

Chengdu and Chongqing are densely populated with universities and boast abundant scientific research resources. Leveraging this advantage, LADIC collaborates with local universities and research institutes to tackle key technologies in metal powder production—from smelting processes to powder purity control—ensuring that “innovation from 0 to 1” happens in Chengdu and Chongqing. Luzhou, benefiting from its well-developed chemical industry infrastructure, strong policy support, and ample production space, quickly absorbs these achievements and has established the largest metal powder base in Southwest China, with an annual capacity exceeding 2,000 tons. This not only satisfies local demand but also serves enterprises across Southwest and East China. This production capacity ranks among the top metal powder production bases nationwide and can meet the annual powder requirements of nearly a thousand small and medium-sized additive manufacturing enterprises, providing robust support for the industrial chain to ensure a stable supply of raw materials.

The model of “R&D in Chengdu and Chongqing, manufacturing in Luzhou” not only addresses the challenges of “inability to produce or produce well” in materials, but also leverages complementary strengths to closely integrate the innovation and industrial chains of both regions, laying a solid foundation for additive manufacturing to enter thousands of households. In the midstream segment of the industrial chain, LADIC has equipped production with a true “core engine”—creating “Sichuan-made” precision equipment capable of printing large-size metal parts. With operation simplified to the level of a “point-and-shoot camera” and doubled efficiency, this innovation fills the gap in high-end domestic equipment, ensuring precision manufacturing is no longer dependent on foreign technology. In the downstream segment of the industrial chain, technology truly takes root in daily life, yielding fruitful results: In aerospace, a 30,000-square-meter “super factory” has been built, serving more than 60 clients and establishing itself as a national demonstration project. In healthcare, leveraging the resources of Luzhou’s level-A tertiary hospitals, precision medical devices are developed to conform to human body contours, enabling doctors to treat patients more accurately and benefiting a broader patient population. In mass consumer goods, a pair of sneakers meeting the rigorous standards of leading international luxury brands can be manufactured in just 2 hours—ten times the efficiency of traditional handmade shoemaking and three times the output of conventional production lines. Luzhou-made fashionable sneakers, with a daily output of four to five thousand pairs, are transitioning from cutting-edge laboratory technology to the feet of global consumers. This is not only a revolution in shoemaking efficiency, but also a vivid example of LADIC taking additive manufacturing as a breakthrough to drive the transformation of the industrial chain—from overcoming critical bottlenecks to venturing onto the global stage.

Breakthrough: Building a corporate moat

From designer toys to precision aerospace components, from custom medical implants to sneakers produced in just two hours via 3D printing, LADIC has transformed additive manufacturing into an industry cornerstone in just three years. Of greater interest than technology itself is how this local state-owned enterprise unlocks the deeper drivers of new quality productive forces.

When additive manufacturing was still seen as a niche technology, LADIC entered the market as an industry pioneer. Confronted with doubts about the feasibility of high-end manufacturing in a third- or fourth-tier city, it made precise decisions to cut non-core businesses and sharpen its focus on technological R&D and fostering the industry ecosystem. This strategic streamlining paves the way for innovation, enabling the company to establish itself in high value-added sectors such as aerospace, accumulate its first pot of gold, and use systems thinking to build robust upstream and downstream industry networks.

The story of breakthroughs and innovation was forged not by any single party, but through the concerted efforts of scientists, entrepreneurs and governments. In building industrial networks, research institutes act as the “roots” deeply embedded underground. LADIC, together with Huazhong University of Science and Technology, Northwestern Polytechnical University, and other institutions, has collaboratively established a national innovation center, securing the core technologies of additive manufacturing and forming a strong competitive moat for the enterprise.

The government serves as both a “guardian” that embraces innovation—implementing a “trial-and-error tolerance” mechanism to ensure innovative activities, converting short-term mistakes into long-term valuable experience—and as an “enabler” of local resources. Leveraging Luzhou’s unique industrial strengths in medical care and equipment manufacturing, and the resource integration capability of state-owned platform companies, it networks capital, technology, and market resources, providing targeted support for the extension, supplementation, and strengthening of emerging industrial chains. At the financial level, data shows that since the 14th Five-Year Plan, Luzhou City has assisted enterprises in obtaining credit loans totaling 14.412 billion yuan, with manufacturing and technology enterprises benefiting most. This has established a virtuous cycle of “industrial growth—credit accumulation—financial support—further development,” reinforcing both the resilience and vitality of industrial clusters.

Entrepreneurs’ market acumen and resource integration capabilities serve as the “soil” nurturing these “roots”—leveraging the resource strengths of state-owned capital, attracting social capital to jointly build funds, facilitating a positive cycle of R&D and market application, and transforming laboratory “samples” into large-scale deliverable “products.” The youthful management team demonstrates keen strategic foresight: They proactively traveled to the Yangtze River Delta and the Guangdong-Hong Kong-Macao Greater Bay Area for research and learning, integrating advanced practices with local strengths, and deploying forward-thinking global strategies—on one hand, “bringing in” global innovation resources to overcome development bottlenecks; on the other, “going global” by taking root at strategic locations such as Hainan and Xinjiang, connecting with Southeast Asia and RCEP markets through the free trade port, reaching the Russian energy belt via Central Asian gateways, and facilitating “dual land-sea circulation” through differentiated ports.

Today, LADIC leverages its Hainan base to serve Southeast Asia and extends its reach to Central Asia via Xinjiang ports, driving manufacturing upgrades along the route through high cost-efficiency and tailored solutions. This not only provides a replicable model for industrial collaboration under the joint development of the Belt and Road Initiative, but also strengthens the international influence of China’s high-end manufacturing.

【未经授权,严禁转载!联系电话028-86968276】